I came across a good deal on a commercial refrigerator and freezer. Good condition, lightly used, fit in the space available and roomy enough for the second Marines. It also allowed me to pass on to my daughter my old fridge/freezer in similar condition (detailed in The Road Trip). But behind every silver lining there is a cloud waiting to rain on your parade.

No ice maker.

Going to the convenience store every other day for ice soon took its toll on our patience. My options were to continue to buy individual bags of ice as needed, acquire a stand-alone ice maker or make an ice maker for this freezer. Stand-alone ice makers come in residential and commercial varieties. The residential types have horrible reputations and take up counter space. Commercial varieties are as expensive as what I’ve already spent for the fridge/freezer combo already.

Google to the rescue.

Some very enterprising folks have figured out that installing a universal ice maker kit (about $50) into a stand alone ice chest (about &150) will provide lots of ice for their party house on the lake, supply the frat house needs for those important parties or whatever.

So. I went shopping and got a generic Frigidaire ice maker kit. I say generic because almost all ice maker kits are the same except for the electrical plug and mounting templates. The function and design are pretty much the same. I figured that if I got real creative, I could mount the parts into my new-to-me freezer compartment.

First, I had to do get an electrical diagram of the ice maker. This freezers runs off 120 Vac. But within the freezer, I wondered if the engineers used some fancy-smancy transformer to drop the voltage to 24 Vdc or something to run the internal mechanisms. No problem, I’m an electrician and can read electrical diagrams. But, for the life of me, I could not find any electrical diagrams for any ice makers on the web! Google failed! Until I figured out that the electrical diagrams for ice makers were in the electrical diagrams of the fridge/freezer electrical diagrams for which they were intended to be installed. OK. Got that whipped. It only took me about a month to figure that out.

Well, that’s not the ice maker’s electrical diagram, it’s just for demonstration purposes, but you get the point.

Turns out, ice makers run off 120 Vac, also. Plain and simple. Four wires from the ice maker are 120 Vac hot, neutral, ground and one to control the solenoid for the water valve. Each ice maker has a specific plug for those 4 wires depending on the make/model of fridge/freezer. All I have to do is find the plug-mate for the model that I chose. I think mine was for some version of Frigidaire. Google fail! No such thing. Or at least, I couldn’t find it. It took me a couple of months to give up on that search.

So, what could I use for a 4-wire plug that was cold and water tolerant? Eureka, a trailer wiring harness! Perfect!

Mounting the whole shebang was a bit daunting. I had to drill a hole in the wall of my freezer compartment. Besides the concept of drilling a hole, I had to avoid the refrigerant coils which manufacturers wrap around the freezer compartment to, well freeze it. They are under pressure and are filled with liquid refrigerant. I mounted the the ice maker under one of the racks in the freezer compartment, the solenoid onto the back wall of the freezer and ran the 1/4″ vinyl plumbing for the water supply. Where I drilled the hole for the water supply to run through the freezer compartment wall I used that expanding foam spray to re-insulate it (OCD at it’s finest). I tapped into the 120 Vac service entrance and had a functioning ice maker. Right? No! It made one tray of ice cubes and stopped.

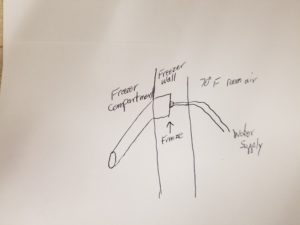

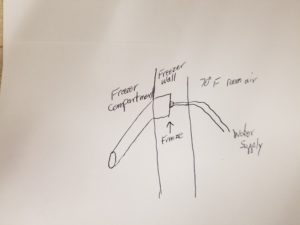

I brought out the trusty-old electrical volt meter and determined that my wiring was all correct and still functioning. The plumbing was intact and there were no leaks. But, there was no water in the ice cube tray. After a few very carefully chosen words and some contemplation, I found that the water line was frozen at the entry point into the freezer compartment. If I disassembled the plumbing, thawed it out and reassembled it, the ice make worked fine. For one tray of ice cubes. Then it froze again. The excellent foam insulation allowed the cold side of the freezer to be able to get to the water input side and freeze it. In the factory designed plumbing, the 1/4″ water supply line meets the 1/2″ tubing that fills the ice cube tray. The solenoid (not shown) allows just enough water to flow through the line, fill the tray and at that point the 1/2″ line will be empty of water and thereby not freeze. Only in my application, it did freeze. Figuring this out took a couple of days.

Factory water entry diagram

So, how does the water get from the 70′ F room temperature input line into the subzero freezer compartment without freezing? I don’t know how the engineers of the model of Frigidaire this kit was made for thought it was supposed to work, but I had a few ideas of how I was going to do it here.

The first thing I tried was to carve out the spray-in foam I so thoughtfully applied. I thought doing this would allow the warm room temperature air to circulate and prevent the freeze zone from freezing the incoming water. It was a good idea, but it didn’t work.

Compressed gas cooling systems work by using the compressor/coil/fan system to extract heat to lower the temperature of the compressed gas which then cools the interior compartment of the fridge/freezer, right? So, I figured I could make a plenum to capture that heat and duct it to the area that was freezing. I liked this idea as it required no extra energy to function. But, it does require sheet metal and sheet metal bending skills, both of which I have.

Alternatively, I could use a night light. You know, one of those little 4 watt light bulbs stuck in the hole to keep the freeze prone area from freezing. Generations of people have used this technique (every since Thomas Edison burned his fingers changing a hot light bulb) to keep pipes from freezing. This was my least favorite solution. First, it used additional electricity, albeit very little. Secondly, it would fail. All light bulbs fail (hence Thomas’ burned fingers). But, now-a-days one could buy a heater cord that looks like an extension cord that wraps around a water supply line and keeps it above 40′ F. It also plugs into a 120 Vac outlet. Still not the elegant solution I was looking for.

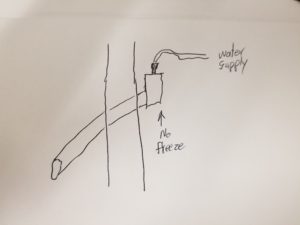

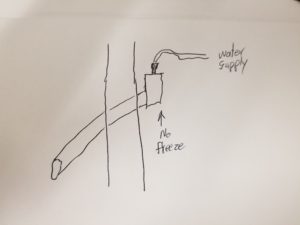

Then, I realized I just had to move the freeze prone area out of the freeze prone zone into the 70′ F room air area! The gizmo that the engineers designed had to be re-engineered. So, I used 6″ of vinyl 1/2″ID tubing, a 1/2″ barbed to 1/2″ NPT connector and a 1/2″ NPT PVC cap. The cap was drilled and tapped to receive a 1/4″ compression fitting to attach to the water inlet line. This contraption was placed so that the union was outside the freeze zone area. Subtle but different when compared to the factory diagram above. We are not about 5 months into this project, but…

Voilà! We have ice. Repeatedly.

Your grumpy Uncle/Brother Dave now has ice cubes.

Weary